05.08.2020

Since this series began in May, the UK has come out of lockdown but the impact of Covid-19 on supply chains remains. The pandemic has without doubt influenced how manufacturing supply chains will evolve in the coming years, and how as businesses, you can best manage them.

In our last blog of the six-part manufacturing smart supply chains series in partnership with Oracle, we will be focusing on what trends we expect to see, as well as what supply chains may look like in the next two years.

Intention to re-shore is growing

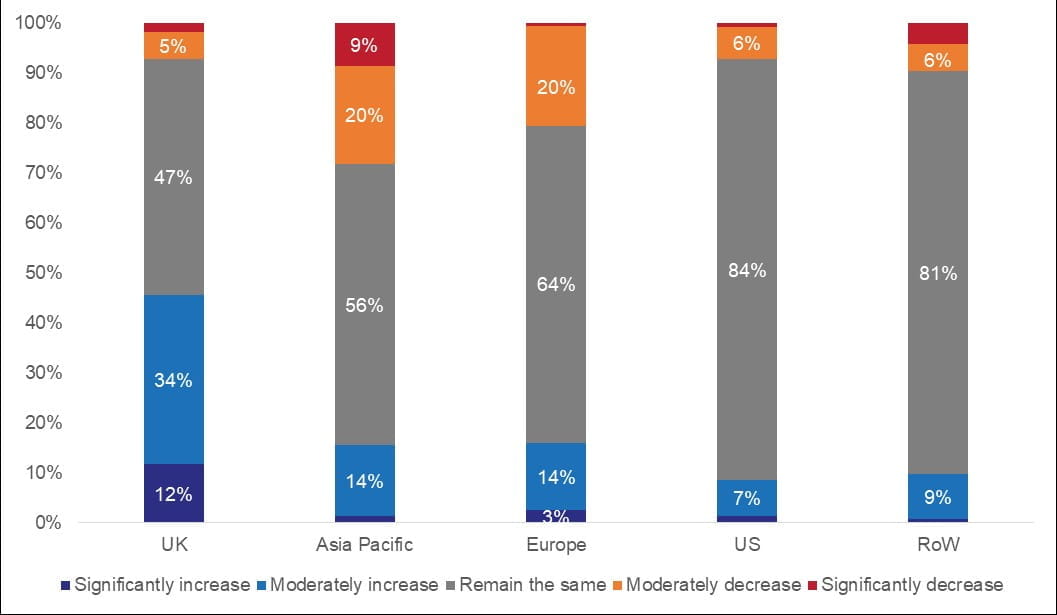

Bringing manufacturing back to the UK is a hot topic. Our survey found over a third of manufacturers reported that they intend to moderately increase their use of UK-based suppliers in the next two years, with a further 12% indicating a significant increase. This is different to previous years which showed manufacturers had not significantly increased the number of UK suppliers.

Graph 1: How do you anticipate the proportion of your company's suppliers will change in the next two years?

Source: Make UK / Oracle survey, June 2020

Whilst this is only the intention to re-shore, it does indicates that manufacturers are beginning to address the international supply chain risks highlighted by Covid-19. Evidently manufacturers are looking to diversify their supply chains as a way of spreading risk, and exploring the options to use local suppliers is one option. Increasing their use of local suppliers was in the top three strategies manufacturers reported to have undertaken to improve their supply chain performance.

Data driven supply chains

In addition to increased use of local suppliers, increased collaboration was one of the top three strategies manufacturers said they will undertake to improve supply chain performance. The use of data is critical in establishing the successful collaboration necessary for smart, resilient supply chains – but to date, too few manufacturers are using digital solutions to improve supply chain performance (6%).

Accurate data can improve supplier selection, manage relationships and provide real-time analysis to increase agility and predict future shocks. Coupled with automation, predictive analytics will enable businesses to quickly adapt to changing environments, customer needs and commercial demands.

In short, data will provide the foundation on which resilient supply chains are built. The low adoption of digital supply chain technologies by manufacturers is worrying.

UK manufacturing has proven critical

- Aim for the UK to be in the top five manufacturing nations in the world (we are currently 9th)

- Work with the sector to effectively map out a global supply chain resilience programme.

- Agree coordinated action with key economic partner countries to maintain current trade flows and removing administrative restrictions;

- Support manufacturers to trade globally using smart supply chains

Modern manufacturing needs modern supply chains

This series of blogs in partnership with Oracle has demonstrated that the world in which manufacturers operate is changing and that not all shocks can be predicted. Building agile, connected and smart supply chains will be an essential component in manufacturers’ post Covid-19 resilience. Taking advantage of digital solutions, working collaborating and learning best practice will all prove to be useful as we attempt to reposition ourselves in a new global environment.

Want to know more about how Oracle can help? Transforming the future of industrial manufacturing demands a scalable cloud platform. See how Oracle can help you start your ideal journey to the cloud. Learn more here.

Read our previous blogs:

- Blog one - Manufacturing Supply Chains Today – the Evolution from Supply Chains to Networks and Potential Disruptors

- Blog two - Lasting impact of geopolitical events – how global events disrupt UK manufacturing supply chains

- Blog three - Learning and applying lessons from geopolitical crisis to build resilient supply chains

- Blog four - What can manufacturing supply chains learn from Covid-19?

- Blog five – What are manufacturers doing now to build smart supply chains?

Watch our first webinar here

For more information:

- Blog authors: Bhavina Bharkhada (Make UK Senior Campaigns & Policy Manager) and David Fagan (External Affairs Executive).

- Get involved in the conversation @MakeUKCampaigns @SCMOracle @OracleERPCloud #MakeitSmart