Digitalisation is one of the biggest challenges, but also one of the greatest opportunities for UK manufacturing. Although changes to the way businesses operate may often seem daunting, there’s plenty of evidence that tells us that by adopting new technologies firms can become more resilient, more efficient and importantly more productive - especially in times of crisis like a global pandemic.

At last week’s Digitalising Manufacturing, Reality Driving Digital conference, organised by the Manufacturing Technology Centre (MTC), it was clear that many British manufacturers are already embracing digitalisation. Speaker after speaker -from business owners and corporate CEOs to academics and policy makers - were sharing their stories and ideas about the best ways of adopting new digital technologies, and how to reap the benefits such adoption brings.

1. The role that the adoption of Industrial Digital Technologies have played in supporting national efforts during the pandemic

2. The pandemic broke down previously perceived barriers around remote working

3. Digital and green go hand-in-hand

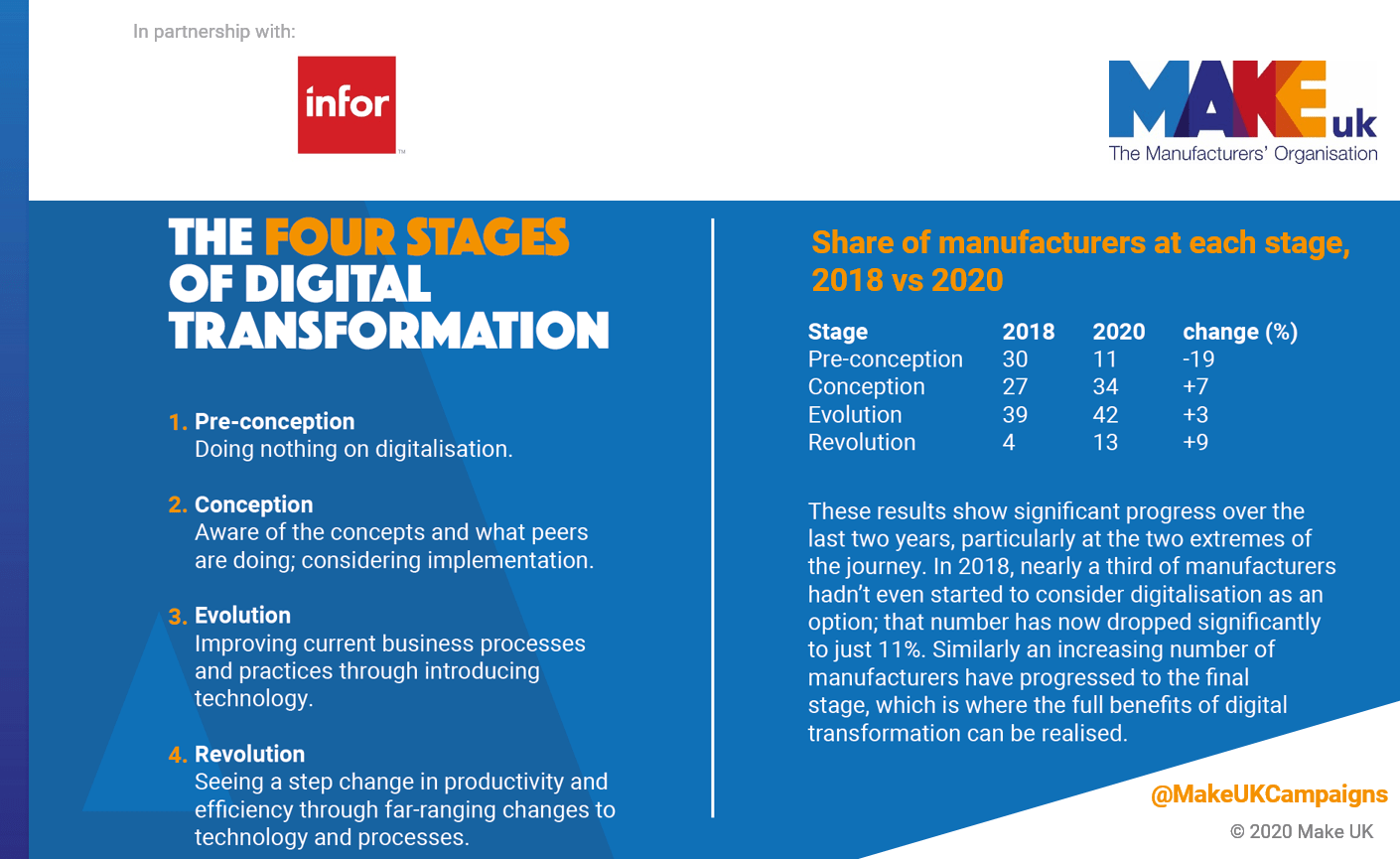

Where is British manufacturing on its digitalisation journey?

We are moving into the right direction.

Barriers to adoption remain

However, our research also shows that we need to overcome some barriers because adoption of IDTs is not across the board.

For example, 45% of manufacturers are aware of the benefits of using predictive maintenance – it will cut the cost of running repairs for example – but very few are adopting it. Why is this the case?

A lack of digital skills and technical knowledge are the main barriers preventing businesses from jumping on the 4th Industrial Revolution wagon. Also climbing the ranks this year is access to finance – possibly driven by the economic downturn from the pandemic. Not doing where to get the right information also remains a barrier that many SMEs face.

Yet there are many platforms through which SMEs can seek support, but, as the Make UK policy paper published in March 2020 found, for many SMEs they can be confusing and misleading.

When it comes to access to funding support, our Innovation Monitor found that 76% of manufacturers aren’t aware of Industrial Strategy Challenge Fund and 78% are not aware of Horizon 2020. The Government funding schemes are often not easy to understand for a busy CEO of a SME and its applications processes are too grand for them to swallow. We need to make them simpler.

Manufacturers are planning to invest in innovation and 4IR but may need some help on the way

70% of manufacturers do want to invest and are planning to increase? Spend on R&D over the next two years - this is really encouraging. Such investment means manufacturing can create more high quality, well paid jobs for vibrant communities.

There is a lot that the government can provide in terms of support and the range of choice is useful, but it can be misleading, very often compared to a post code lottery, with inconsistent programmes.

A quick fix to this is one that Make UK has been calling for - the national roll out of Made Smarter Programme. Our report shows 20% of small businesses in the North West area, where Made Smarter pilot operates, are in the revolution phase of adoption (see graphic above), second only to the South East at 33%. This demonstrates that the model is working and makes the case for its roll-out nationally to make bespoke, dedicated support to manufacturing SMEs consistently available across the country.

A refreshed Industrial Strategy will provide greater opportunities for digital adoption

The government is apparently “refreshing” its Industrial Strategy which will focus on science and technology, green energy and levelling up the regions.

Government should use this moment of change as an opportunity to work with industry and keep the conversation going as to how to re-think business. We now know adopting new digital technologies makes businesses more resilient and competitive – let’s do more of it.

The emphasis from those who shared their success stories at the MTC Conference was on the need to be adaptable, to invest in people and to look for improvements. Being a diverse and inclusive business and investing in green energy will pay itself back.

Be an industrial magpie

As Make UK’s Charlotte Horobin said while closing the conference, “manufacturers need to embrace and accept digitalisation. Be curious – be an industrial magpie take good examples from across all different people within manufacturing and apply it to your business”.

“Don’t forget people - invest in your leaders, manage change, upskill for the future & embrace the next generation. Use the positive momentum behind UK manufacturing to carry on promoting the sector as a highly-skilled, rewarding and well-paid sector to work in"

UK manufactures must seize the moment, embrace digitalisation to get us through the crisis, into recovery and build a new, digital, economy.